TBzTD-70

Composition:70% Tetrabenzyl thiuram disulphide, 30% Carriers and dispersing aids

Appearance:Light yellow particles

Density:Approximately 1.15g/cm3

Filtration(μm):120

Description

TBzTD Masterbatches is an environmentally friendly thiuram accelerator because tetra benzyl nitrosamine is not carcinogenic. For NR, SBR, EPDM, and NBR vulcanization systems, it can be used as a fast main accelerator or secondary accelerator. It has a safer and longer scorch time than TMTD and can be used as a PVC rubber vulcanization inhibitor.

Function

JXBHgran TBzTD-70 can accelerate the vulcanization of natural rubber and synthetic rubber with high processing safety, and shorten the scorch and curing time. JXBHgran TBzTD-70 can not only be the main accelerator but also a thiazole auxiliary accelerator in the presence of sulfur. It can also be used as a sulfur-free system curing agent. It can improve the vulcanized rubber heat aging resistance characteristics without sulfur cross-linking or a small amount of sulfur cross-linking.

Dosage

0.2-2.0 Phr.

Application

Mainly used for tire treads, hoses, conveyor belts, rubber shoes, and other industrial products.

Packing

25 kg/ box.

Storage

25 kg in a carton box with a polyethylene bag liner.

Chemical Properties

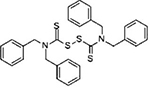

Chemical name: Tetrabenzyl thiuram disulfide

Molecule formula: C30H28S4N2

Molecule structure:

Molecular weight: 544

CAS number: 10591-85-2

| Technical indicators: | Appearance: light yellow powder Initial melting point: ≥128℃ Heating loss: ≤0.3% Ash: ≤0.3% Residue on 150μm sieve: ≤ 0.1% Residue on 63μm sieve: ≤ 0.5% |